Many of our customers have asked to learn more about how online emission catalyst cleaning actually works. Our post will go into more detail to explain what this process is about and how it works.

The first question that comes up is, how does online cleaning take place if there is no needed access? And what we do is port cutting, either with a vertical or a horizontal flow. What the Groome team needs is to understand about the wall design (the thickness, the insulation depth, and if there is a liner plate); we need to know if there is positive or negative pressure, and we need to see drawings to determine any interior impedances.

Our experienced team then designs custom doors within optimal parameters: the proper size and shape, the correct number of ports, and the needed location and orientation (both relative to catalyst). We ensure that this will be a repeatable process, and define the plant investment.

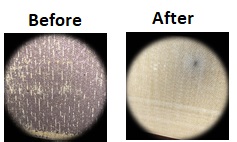

Often the question comes up as to what can be cleaned, which aims to get at the limitations. The answer is Groome completes a thorough cleaning on all makes (name your favorite catalyst OEM!) and all models (whether vintage or between one and ten+ years old). And we work on a variety of designs that include corrugated, extruded, pleated, small or large pitch.

Both SCR and CO emissions catalysts qualify for online cleaning. This is another frequently asked question.

Importantly, Groome works around obstacles. If there is a module Grid that creates pockets of limited access, we have a solution. If there are structural or beam issues, we have a solution. If there is a question about grating or catalyst retention, we have a solution.

And as with all Groome projects, safety is paramount and the prevention of issues is the cornerstone of all we do. We ensure our crews are well trained and well-rested; crew rotation is crucial to mitigate heat exposure. We prepare our crews for high heat conditions and ensure they have the needed hoods, suits, gloves. We supply air when needed. There are MANY other safety precautions we take.

And the primary benefits of online cleaning? They all deliver results and include the delivery of additional revenue opportunities due to no downtime. The plant will run at a much more optimal level. And, the work the Groome team does ensures a sustainable running plan along with repeatable performance so that online cleaning can be conducted again in the future. And, there are more benefits and answers we’d like to provide to the online cleaning opportunity.

And the primary benefits of online cleaning? They all deliver results and include the delivery of additional revenue opportunities due to no downtime. The plant will run at a much more optimal level. And, the work the Groome team does ensures a sustainable running plan along with repeatable performance so that online cleaning can be conducted again in the future. And, there are more benefits and answers we’d like to provide to the online cleaning opportunity.

Watch our 20-minute on-demand webinar to learn more – click here.

This webinar features two Groome speakers who will share all you would like to know about online cleaning:

Steve Houghton, VP of Sales at Groome Industrial Service Group, is well-versed in all the industries Groome represents: HRSG, Refinery, Industrial Cleaning, Surface Preparation & Coatings, and Door & Mechanical Services. Steve has a track record of success in his sales and marketing roles at companies providing industrial supplies and services over his 16-year career. He holds a Bachelor’s Degree of Business from Rowan University.

Raymond Langton, Regional Sales Manager at Groome, has more than 20 years of experience in the Refinery, Petrochemical and Midstream markets, and has also worked in the areas of operations, project management, and sales. He spent ten years with a nested contractor at the Phillips 66 Bayway Refinery, and the last ten years with environmental and industrial service companies. Ray holds a BBA degree from Temple University and an MBA from Thomas Jefferson University.