Catalyst Services – SCR

Groome offers a variety of SCR catalyst services nationwide.

Our quality-driven methods are value-engineered and proven effective.

Benefits include:

-

Maximize flow through catalyst

-

Maximize catalyst life

-

Minimize pressure drop

-

Expose active conversion sites

-

Reduce ammonia slip

-

Minimize pressure drop

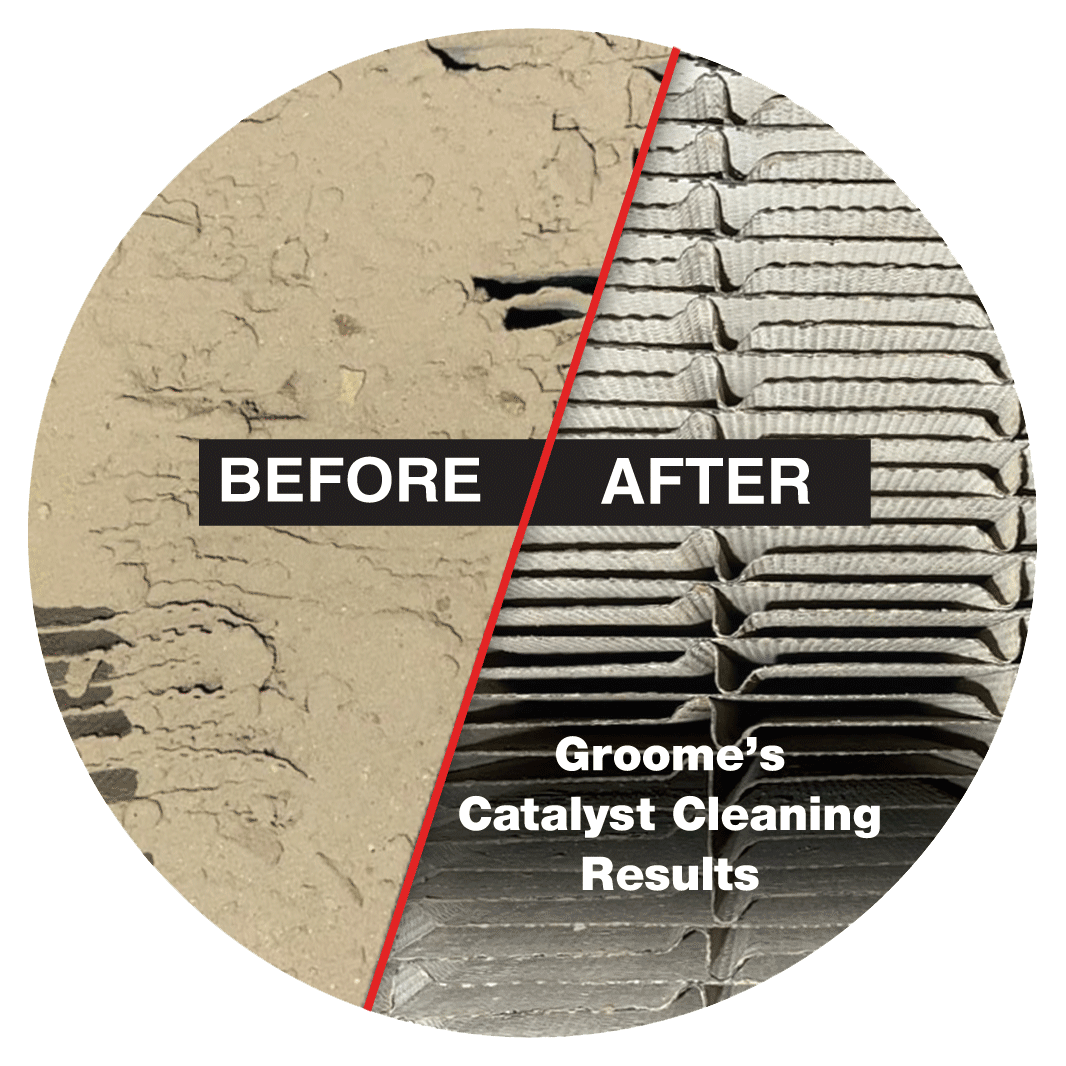

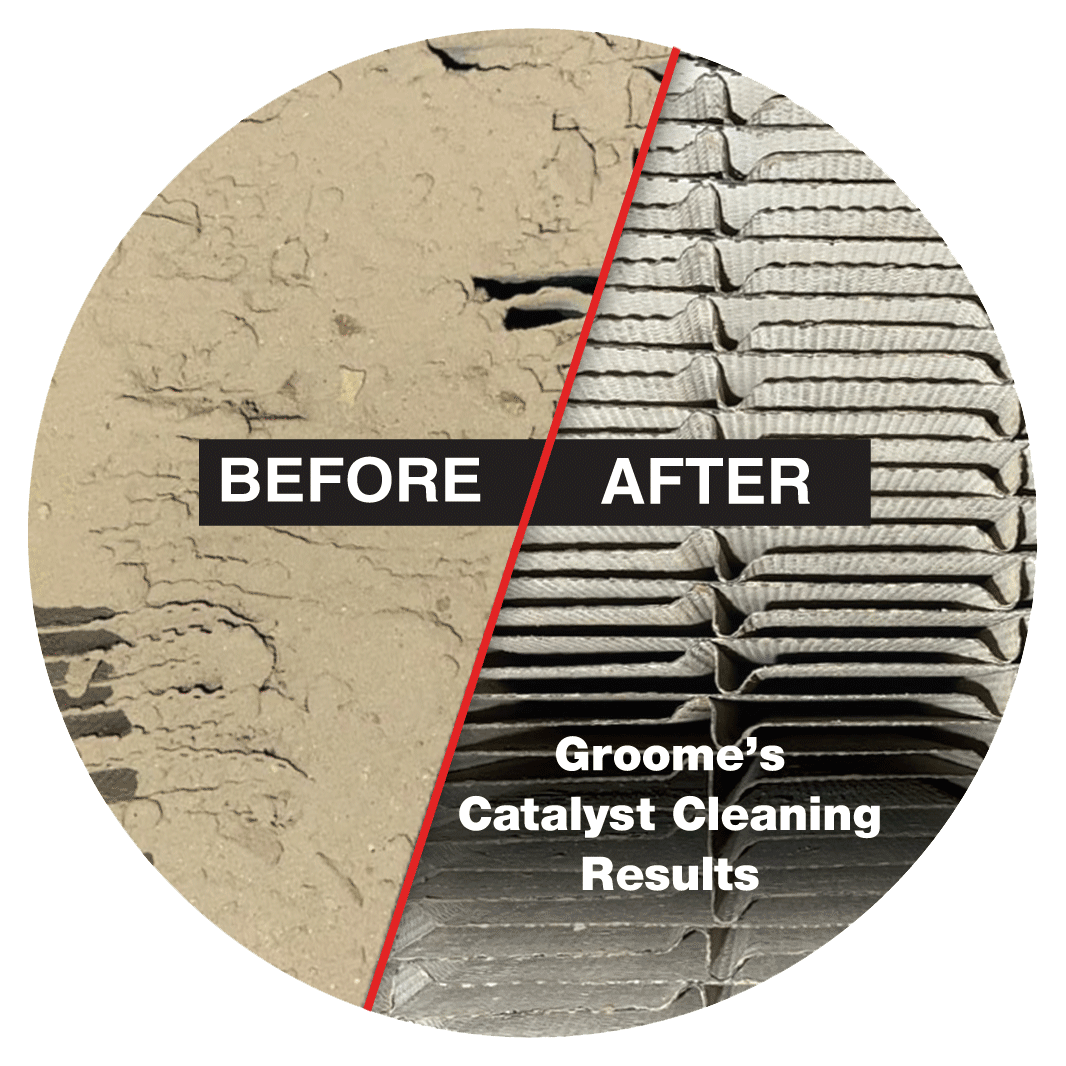

Catalyst Cleaning

Utilizing highly-effective techniques and methods, Groome thoroughly cleans catalysts during a minor or major outage. Our work is completely turnkey, with no subcontractors and minimal plant support required. Our work facilitates increased catalyst performance and delivers a strong ROI.

Catalyst Replacement

We partner with several catalyst OEMs when performing a replacement. The Groome team consists of in-house field engineering crews who are catalyst specialists and are responsible for all scaffolding, crane support, rigging and welding service.

Catalyst Disposal

Our industry partnerships allow us to take the guesswork out of the proper disposal of spent catalyst. Catalysts are transported off-site; all steel is recycled and the catalyst is mechanically deconstructed. Proper paperwork is then returned to the plant for record keeping.

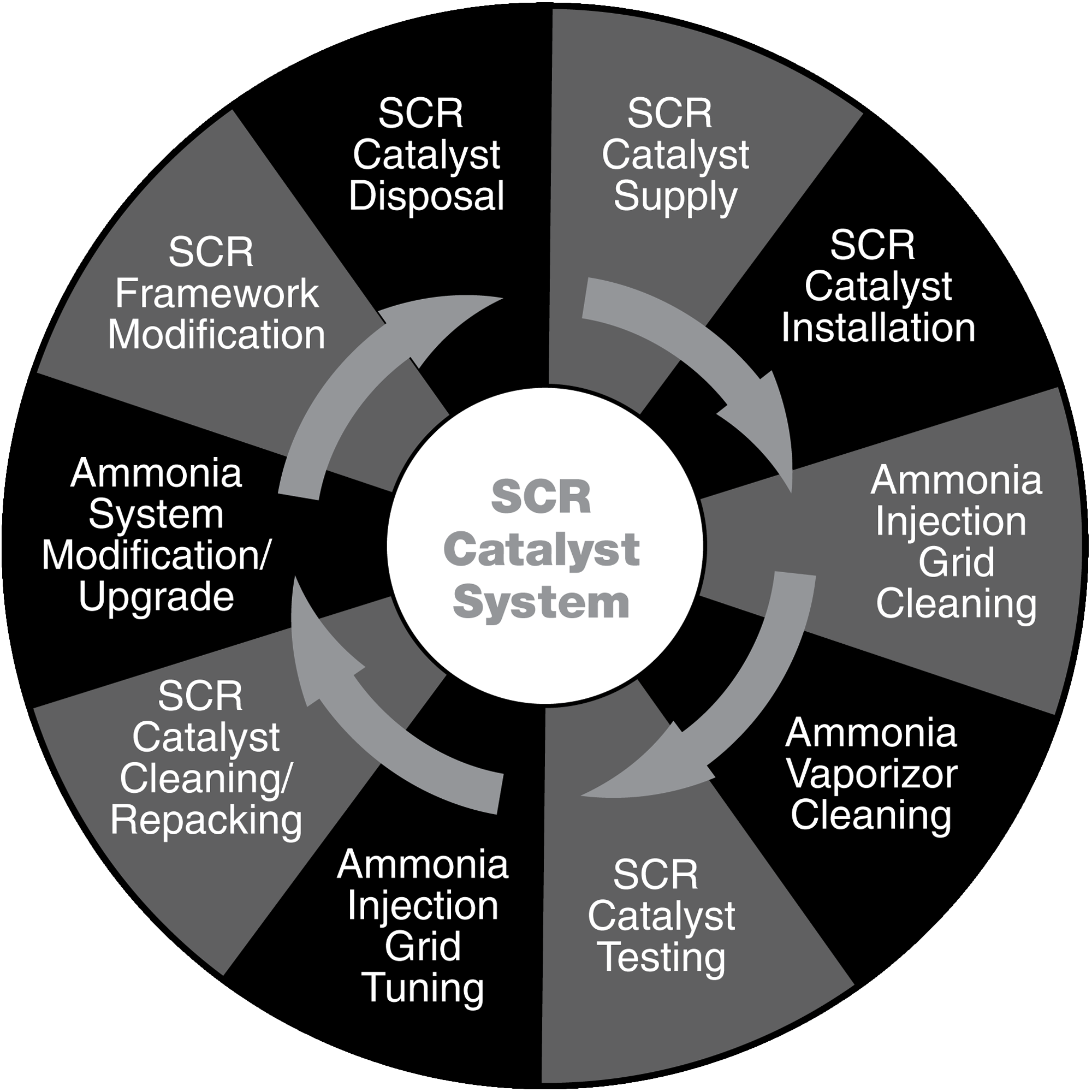

While our focus remains on the entire life cycle of a complete catalyst system, our offerings extend beyond just the catalyst.

SCR Catalyst Systems

• In-Situ Mechanical Cleaning

• Catalyst Evaluation

• Catalyst Testing

• Catalyst Replacement

• Catalyst Disposal

Ammonia Injection Grid (AIG) Services

Tuning A key to improving AIG performance is maintaining proper distribution across the SCR catalyst face.

Our philosophy is simple:

provide quality, innovative services at a reasonable cost.

With over 50 years of providing specialty maintenance and industrial services nationwide,

Groome Industrial Service Group has never been stronger, safer, or more focused on the future than we are today.

Safety is paramount at Groome.

We follow IME/OSHA-based safety training programs, along with an OSHA 30 training standard for all employees.

An accident-free environment translates to lower insurance costs, better employee commitment, higher productivity, and an improved bottom line for our customers.