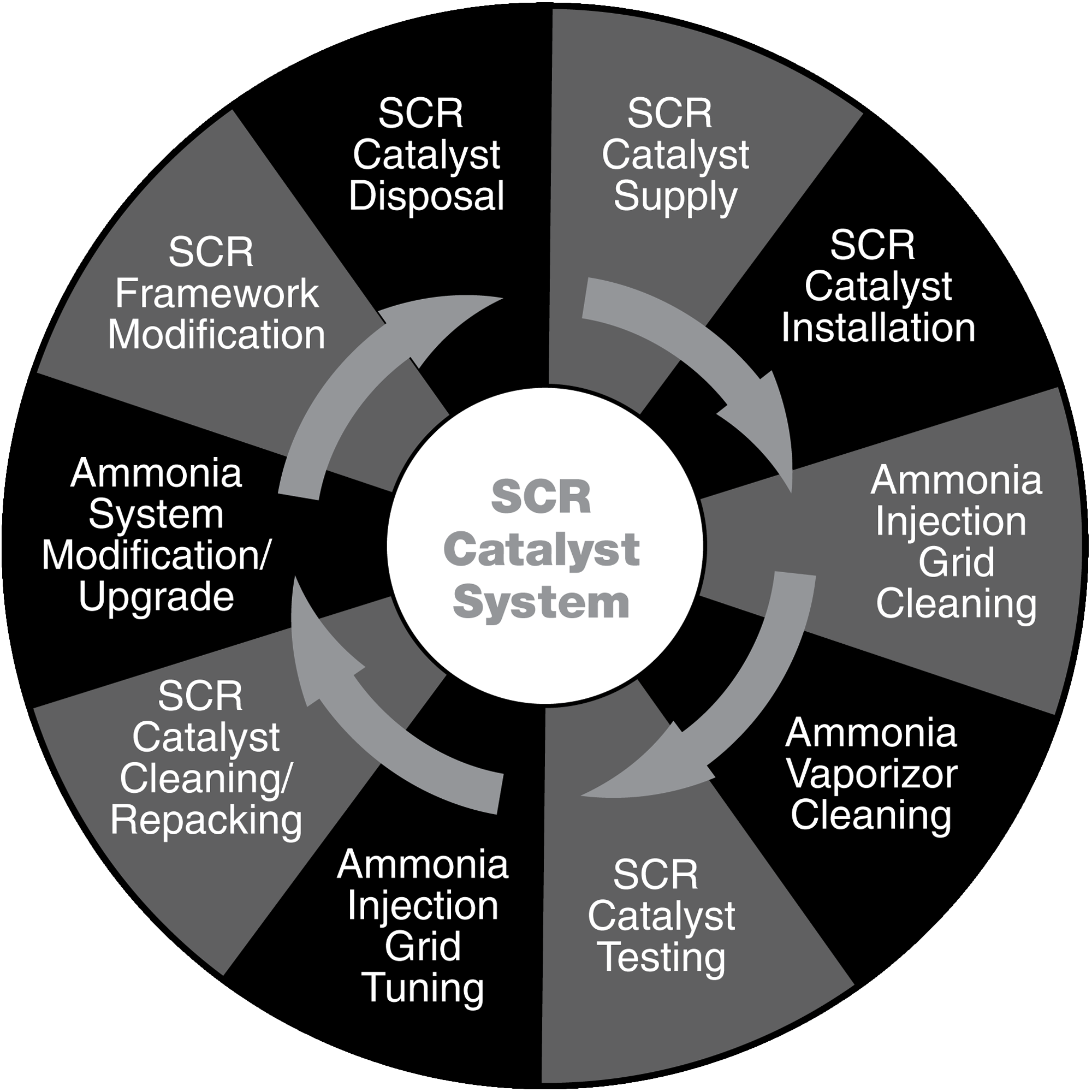

Groome offers a variety of SCR catalyst services nationwide.

Our quality-driven methods are value engineered and proven effective.

While our focus remains on the entire life cycle of a complete catalyst system, our offerings extend beyond just the catalyst.

SCR Catalyst Systems

- • In-Situ Mechanical Cleaning

- • Catalyst Restacking and Repacking

- • Catalyst Evaluation

- • Catalyst Testing

- • Catalyst Replacement

- • Catalyst Disposal

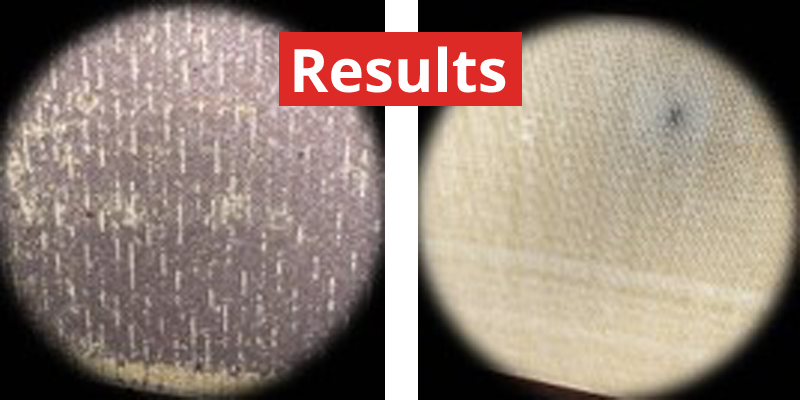

Benefits include:

- Maximize flow through catalyst

- Maximize catalyst life

- Minimize pressure drop

- Expose active conversion sites

- Improve turbine efficiency

- Reduce ammonia slip

Ammonia Injection Grid (AIG) Services

Tuning

Vaporizer Cleaning

AIG Retrofit

A key to improving AIG performance is maintaining proper distribution across the SCR catalyst face.

Vaporizer units are water jetted to remove build-up in the drip rings to maximize system efficiency and performance.

Upgrading ammonia delivery systems to meet new demands of plant performance.

Tuning

A key to improving AIG performance is maintaining proper distribution across the SCR catalyst face.

Vaporizer Cleaning

Vaporizer units are water jetted to remove build-up in the drip rings to maximize system efficiency and performance.

AIG Retrofit

Upgrading ammonia delivery systems to meet new demands of plant performance.

On-line Catalyst Cleaning

SCR cleaning can take place while you continue operations. We have seen the tremendous ROI achieved by continuing to run. Plus, our experience shows that several shifts are all it might take to complete this work.

No access? No problem.

Port cutting, vertical or horizontal flow All we need:

- Wall Design: Thickness, and insulation depth

- Pressure: Positive or negative

- Interior Impedances: Location and design

Vacuum port outcomes

- Custom door design with proper size & shape

- Proper number of ports

- Accessible location and orientation (relative to catalyst)

- Repeatable process (plant investment)

We can clean your catalyst

Groome thoroughly cleans ALL:

- Makes: name your favorite catalyst OEM

- Models: any vintage: 1 or 10+ years old

- Designs: corrugated, extruded, pleated, small or large pitch

Concerned about Stack Particulates?

Online catalyst cleaning employs vacuum pull only, with no downstream blowing. All debris/masking/foulant material is removed from the catalyst, putting up to 27″ of pressure in a vacuum bag, not in the gas path.

| OBSTACLE | | | SOLUTION |

| Limited Access | Custom lance and lance tip | |

| Structure/Beams | Factor for proper port: placement, orientation, size |

|

| Grating/Catalyst Retention | Custom tip: shape and diameter plus vacuum pull |

Our philosophy is simple:

provide quality, innovative services at a reasonable cost.

With over 50 years of providing specialty maintenance and industrial services nationwide,

Groome Industrial Service Group has never been stronger, safer, or more focused on the future than we are today.

Complete Turnkey Solutions.

No Subcontractors.

Minimal Plant Support Needed.

Safety is paramount at Groome.

We follow IME/OSHA-based safety training programs, along with an OSHA 30 training standard for all employees.

An accident-free environment translates to lower insurance costs, better employee commitment, higher productivity, and an improved bottom line for our customers.